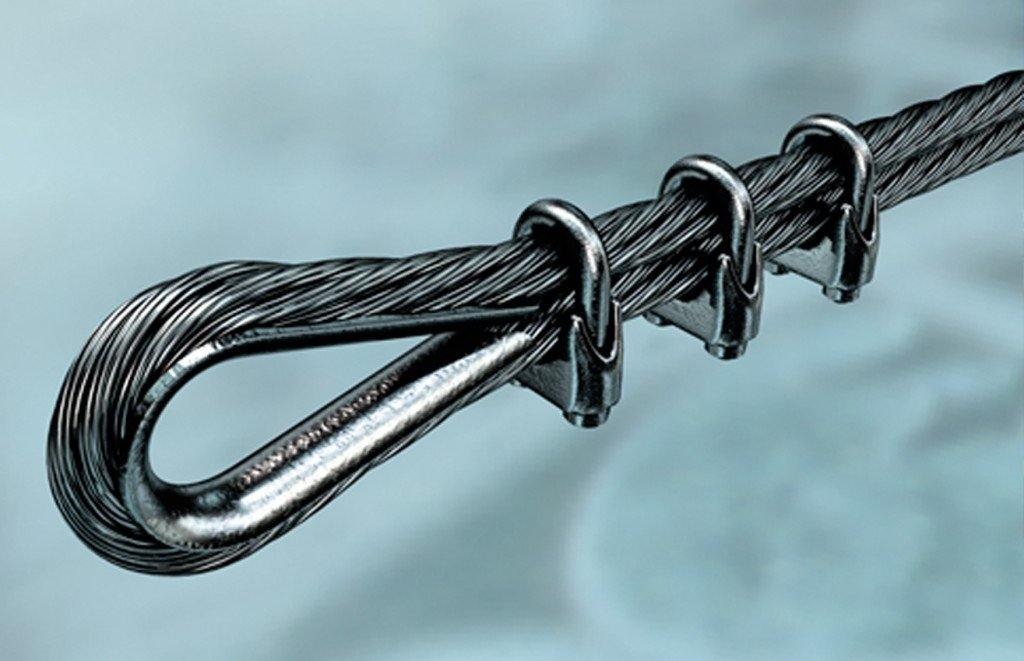

Wire rope clips, also known as wire rope clamps or cable clamps, are simple yet incredibly useful devices that help secure the ends of wire ropes together or create a loop in a wire rope. They are commonly used in a variety of applications, from construction and rigging to boating and agriculture. In this detailed guide, we’ll take a closer look at how wire rope clips work, why they’re important, and provide you with some practical tips for using them effectively.

What Are Wire Rope Clips?

When buying rope for a specific purpose and needing to connect it to something, or wanting to make a loop in it, leaving the rope loose isn’t a reliable option. That’s where wire rope clips come in. These metal clamps are designed to securely hold the ends of wire ropes and to form an eye or loop by holding the rope in place.

The Anatomy of a Wire Rope Clip

To understand how wire rope clips work, let’s break down their basic components:

- U-Bolt: This is the “U”-shaped part of the clip. It resembles a horseshoe or, as some might say, a capital letter “U.” The U-bolt has threads on both ends, and it’s what holds everything together.

- Saddle: The saddle is the curved part of the clip that fits around the wire rope. It’s designed to provide a secure grip on the rope and distribute the load evenly.

- Nuts: Wire rope clips typically come with two nuts for each U-bolt. These nuts are threaded onto the U-bolt and play a crucial role in the clamping process.

Now that we’ve got the components covered, let’s dive into how wire rope clips actually work.

How Do Wire Rope Clips Work?

Wire rope clips work by creating a mechanical connection between the wire rope and itself. This connection ensures that the wire rope remains securely fastened, preventing it from slipping or unraveling. Here’s a step-by-step breakdown of how they operate:

Step 1: Positioning the Clip

Before you start, you’ll need to determine where you want to attach the wire rope or create a loop. Position the clip accordingly, making sure the U-bolt is on the load-bearing side (the side that will experience tension or pull). Discover How Does Traptex Work?

Step 2: Wrapping the Wire Rope

Now, wrap the wire rope around the object or back onto itself to create a loop or secure the rope ends together. The wire rope should be snugly fitted into the saddle of the clip.

Step 3: Inserting the U-Bolt

Place the U-bolt over the wire rope, ensuring that it goes over the saddle and the rope itself. The U-bolt should straddle the wire rope and the saddle securely.

Step 4: Adding Nuts

Thread the nuts onto the exposed ends of the U-bolt. Start by tightening them by hand to ensure they are snugly in place.

Step 5: Tightening the Nuts

Now comes the critical part. You’ll need to use a wrench or pliers to tighten the nuts further. Alternate between the nuts, applying equal pressure to each side of the U-bolt. This is important because it ensures an even distribution of pressure on the wire rope, creating a secure grip.

Step 6: Torquing the Nuts

Continue tightening the nuts until they reach the recommended torque specified by the manufacturer. This torque value is essential to achieve the required clamping force without over-tightening, which can damage the wire rope.

Step 7: Inspecting the Installation

After tightening the nuts to the recommended torque, inspect the installation to ensure that everything is secure and in place. Make sure there are no visible gaps or issues with the wire rope’s positioning within the clip.

Congratulations, you’ve successfully installed a wire rope clip! Your wire rope is now securely fastened or has a loop, ready for use in your specific application.

Why Are Wire Rope Clips Important?

Now that you know how wire rope clips work, you might wonder why they’re so crucial in various industries and applications. Well, wire rope clips offer several key benefits:

- Safety: Wire rope clips provide a safe and reliable method for securing wire ropes. When installed correctly, they prevent the wire rope from slipping or unraveling, reducing the risk of accidents and injuries.

- Versatility: These clips can be used in a wide range of applications, from construction and rigging to agriculture and marine use. They’re suitable for both temporary and permanent installations.

- Cost-Effective: Wire rope clips are an affordable way to terminate wire ropes or create loops without the need for specialized tools or equipment.

- Ease of Installation: Unlike some other methods of wire rope termination, such as swaging or splicing, wire rope clips can be installed with basic hand tools, making them accessible to a wide range of users.

- Field Repairability: In remote or challenging environments, wire rope clips can be a lifesaver. They allow for quick and effective repairs, keeping operations running smoothly.

- Reliability: When installed correctly and maintained, wire rope clips can provide a long-lasting and dependable connection.

Tips for Using Wire Rope Clips Effectively

While wire rope clips are relatively simple to use, there are some essential tips to keep in mind to ensure their effectiveness and safety:

- Choose the Right Size: Select the appropriate wire rope clip size for your application. The size should match the diameter of your wire rope to ensure a secure fit.

- Follow Manufacturer Guidelines: Always follow the manufacturer’s instructions and recommendations for torque values when tightening the nuts. Over-tightening can damage the wire rope, while under-tightening may result in an insecure connection.

- Inspect Regularly: Inspect wire rope clips regularly for signs of wear, corrosion, or loosening. If you notice any issues, replace the clip immediately to maintain safety.

- Proper Spacing: Ensure that you space multiple wire rope clips at the recommended distance from each other. This helps distribute the load evenly along the wire rope.

- Consider Environmental Factors: If your wire rope will be exposed to harsh environmental conditions, such as saltwater or chemicals, choose wire rope clips made from materials that can withstand these conditions, like stainless steel.

- Avoid Saddle Overlap: Make sure there is no overlap of the saddle on the wire rope, as this can reduce the clip’s effectiveness.

- Use the Correct Number of Clips: The number of wire rope clips required depends on the application and the load. Follow industry guidelines or consult with a professional to determine the appropriate number of clips needed for your specific situation.

- Properly Position Clips: Position the clips so that the U-bolt is on the live load side of the rope, where the tension occurs. This ensures that the clip grips the rope securely.

By following these tips, you can use wire rope clips effectively and safely in your projects or applications.

In conclusion

Wire rope clips are simple yet effective devices that play a crucial role in securing wire ropes and creating loops or terminations. By understanding their components and following proper installation techniques, you can use wire rope clips safely and confidently in various applications. Remember to choose the right size, follow manufacturer guidelines, inspect regularly, and consider environmental factors to ensure the longevity and reliability of your wire rope connections. If used correctly, wire rope clips can be a valuable tool in your toolkit for many projects and applications.

FAQs

Now, let’s address some frequently asked questions about wire rope clips to provide you with even more insight into their usage and maintenance.

- Can I reuse wire rope clips?

Wire rope clips can be reused if they are in good condition, and there are no signs of wear, damage, or corrosion. However, it’s essential to inspect them thoroughly before reuse. If there are any concerns about their integrity, it’s best to replace them with new clips to ensure safety.

- Are wire rope clips as strong as other termination methods like swaging or splicing?

The strength of a wire rope clip depends on various factors, including the type and quality of the clip and the correct installation. In some applications, swaging or splicing may provide slightly higher strength and durability. However, wire rope clips are still a reliable and cost-effective option for many applications when installed correctly.

- How do I know if I’ve tightened the nuts on a wire rope clip correctly?

To ensure that you’ve tightened the nuts correctly, follow the torque values provided by the manufacturer in their instructions. You can use a torque wrench to achieve the specified torque accurately. Over-tightening can damage the wire rope, while under-tightening may result in an insecure connection.

- Can wire rope clips be used with coated wire ropes?

Yes, wire rope clips can be used with coated wire ropes, such as those with vinyl or nylon coatings. However, be mindful of the coating thickness when selecting the appropriate clip size to ensure a secure grip on the underlying wire rope.

- Are there any specific maintenance requirements for wire rope clips?

Regular inspection is the key to maintaining wire rope clips. Check them for signs of wear, corrosion, or loosening. If you notice any issues, replace the clips promptly. Additionally, lubricating the threads of the nuts can help prevent corrosion and make future adjustments easier.